AstraBeamLED

OSRAM OSTAR® Stage Light PCB LE RTDUW S2WN

High Power 40W RGBCY LED PCB with direct heatsink copper base.

Production Details

The PCB went into production on April 9, 2025.

- Git Tag:

production-2025.04.09

Received Product

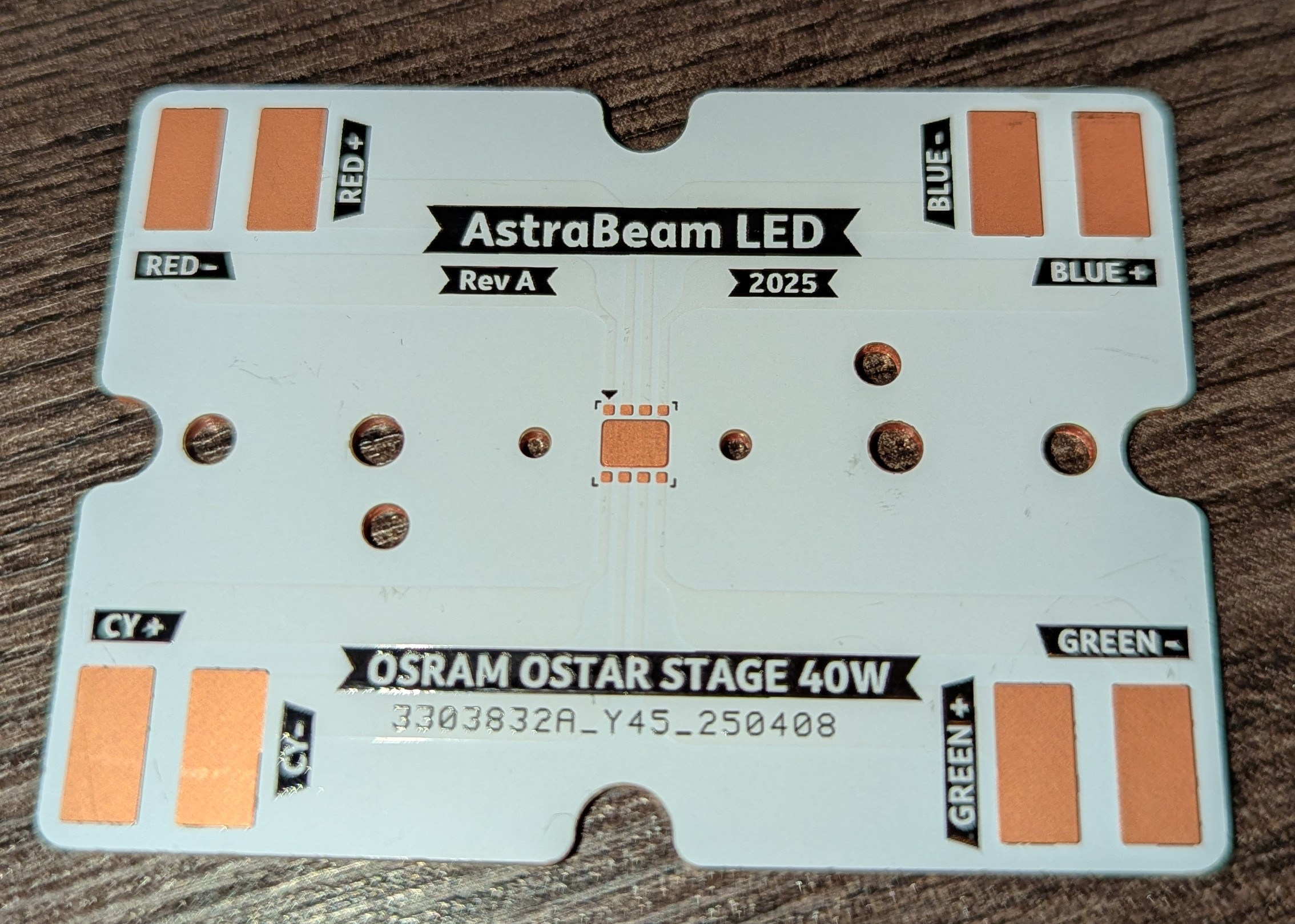

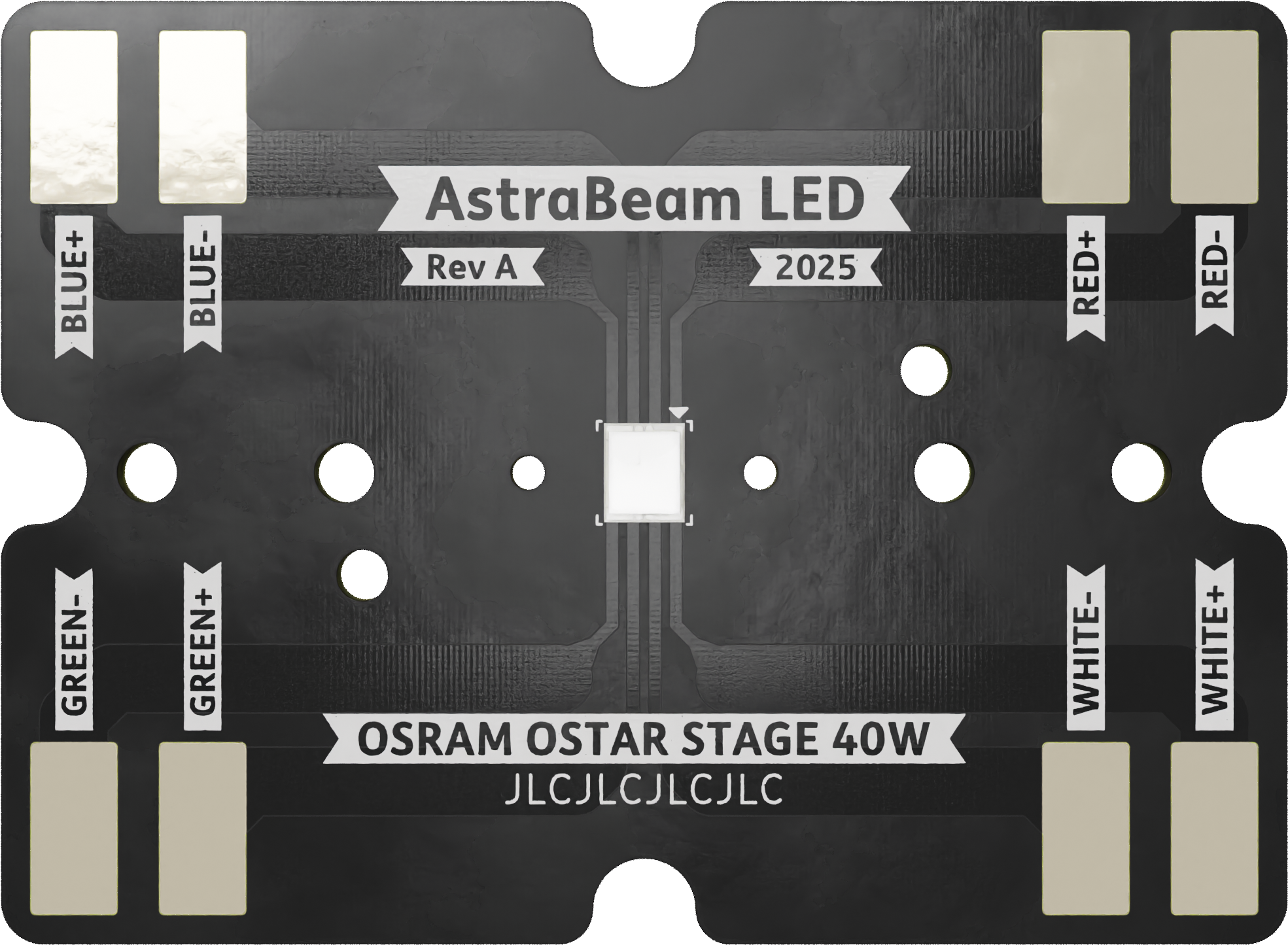

Front

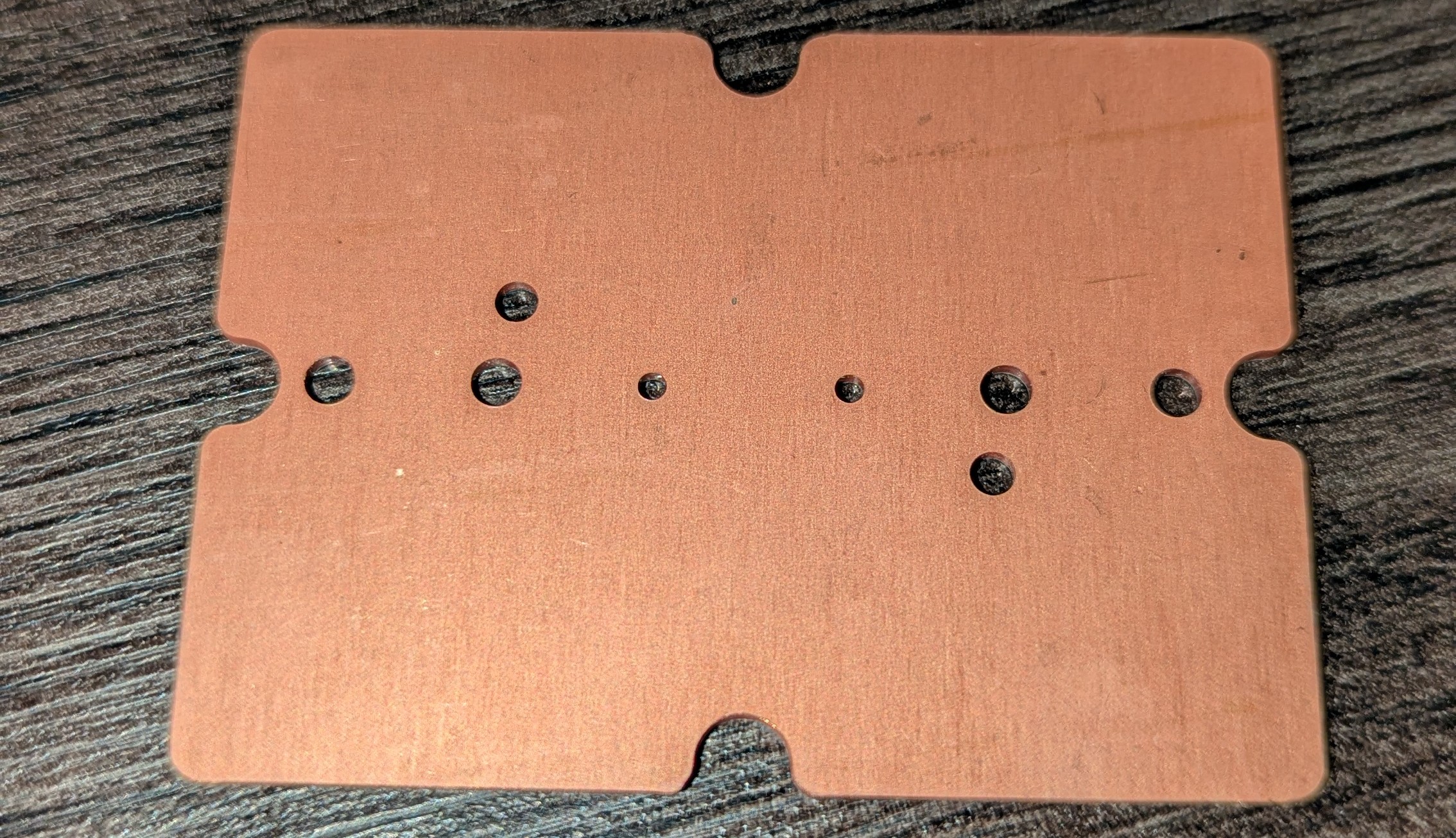

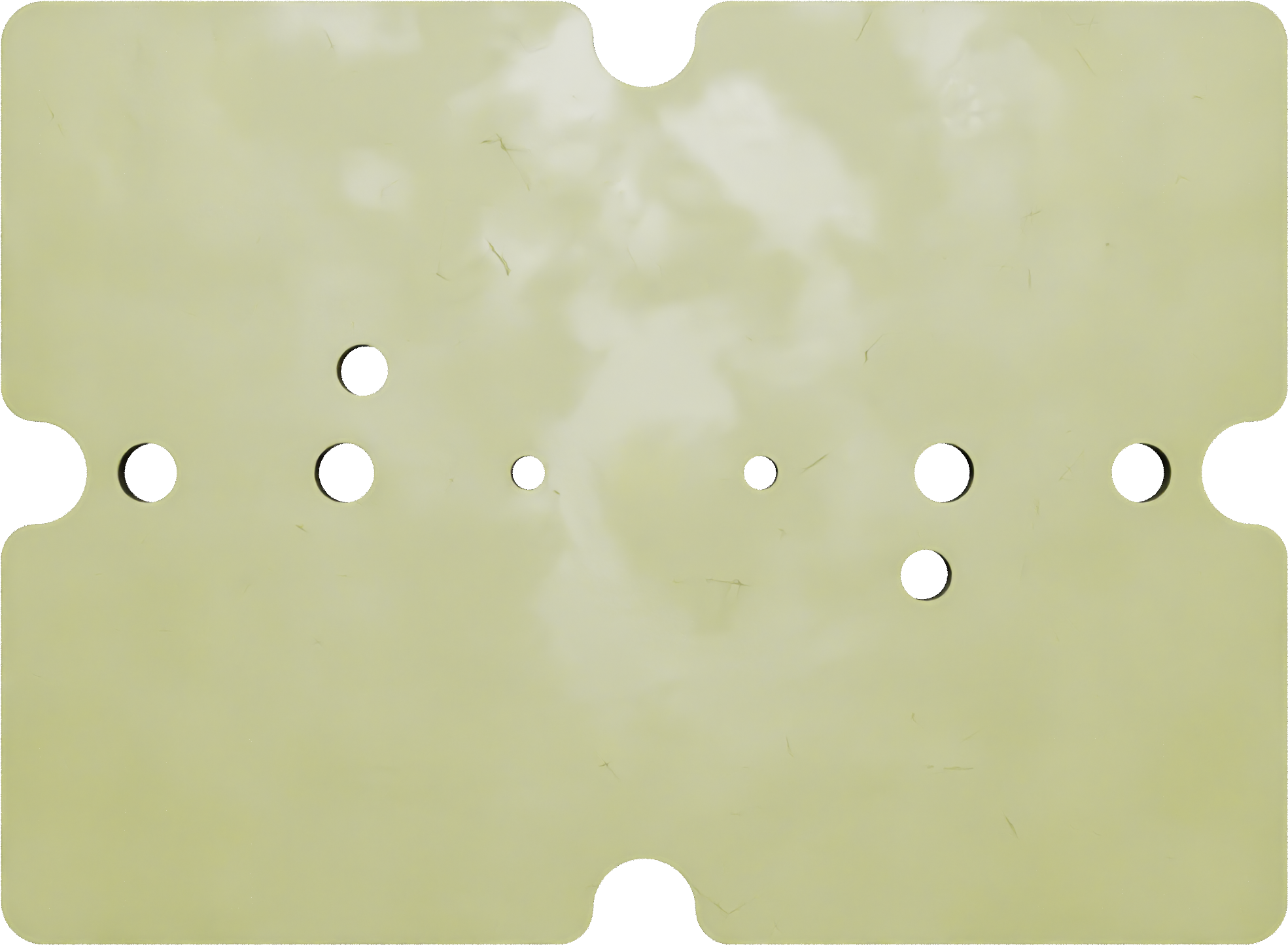

Back

Identified Issues

- Reversed Labels:

The labels for the pins were reversed (1,2,3,4 → 4,3,2,1 for both rows). This occurred because the OSRAM OSTAR LE RTDCY S2WN datasheet specifies pin numbers in the dimensional drawing as if viewed from the flipped side of the chip, rather than the standard convention used in most footprints.- This only affects the labeling. The functionality of the PCB remains intact. For example,

RED-is actuallyBLUE+, etc. - The issue has been corrected.

- This only affects the labeling. The functionality of the PCB remains intact. For example,

- Manufacturer Query:

JLCPCB was unable to determine the dimensions of the direct heatsink and inquired whether to proceed without it.

A response was sent via email, directing them to the fileAstraBeamLED-Direct_Heatsink.gbrincluded in the zip, along with an image specifying the exact dimensions.

Additional Notes

- The edges of the direct heatsink are slightly rounder than expected, with a radius of approximately 1–2 mm.

- The board is notably heavy, which is advantageous for heat dissipation.

- Soldering was performed using 138°C solder paste and a hotplate, successfully attaching an LED without any issues.

Continuous Integration and Repository Status

Table of contents

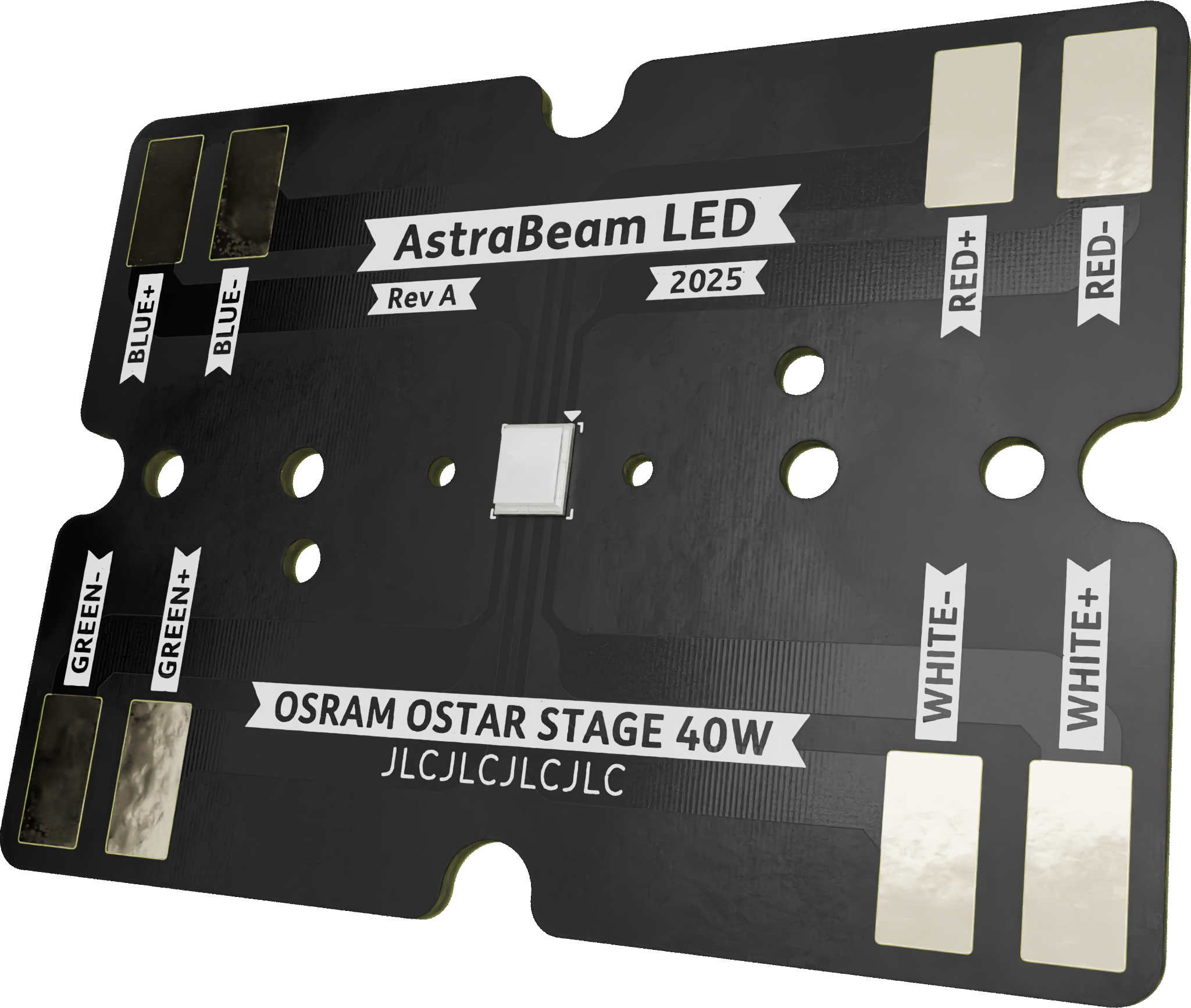

Render Top Angled

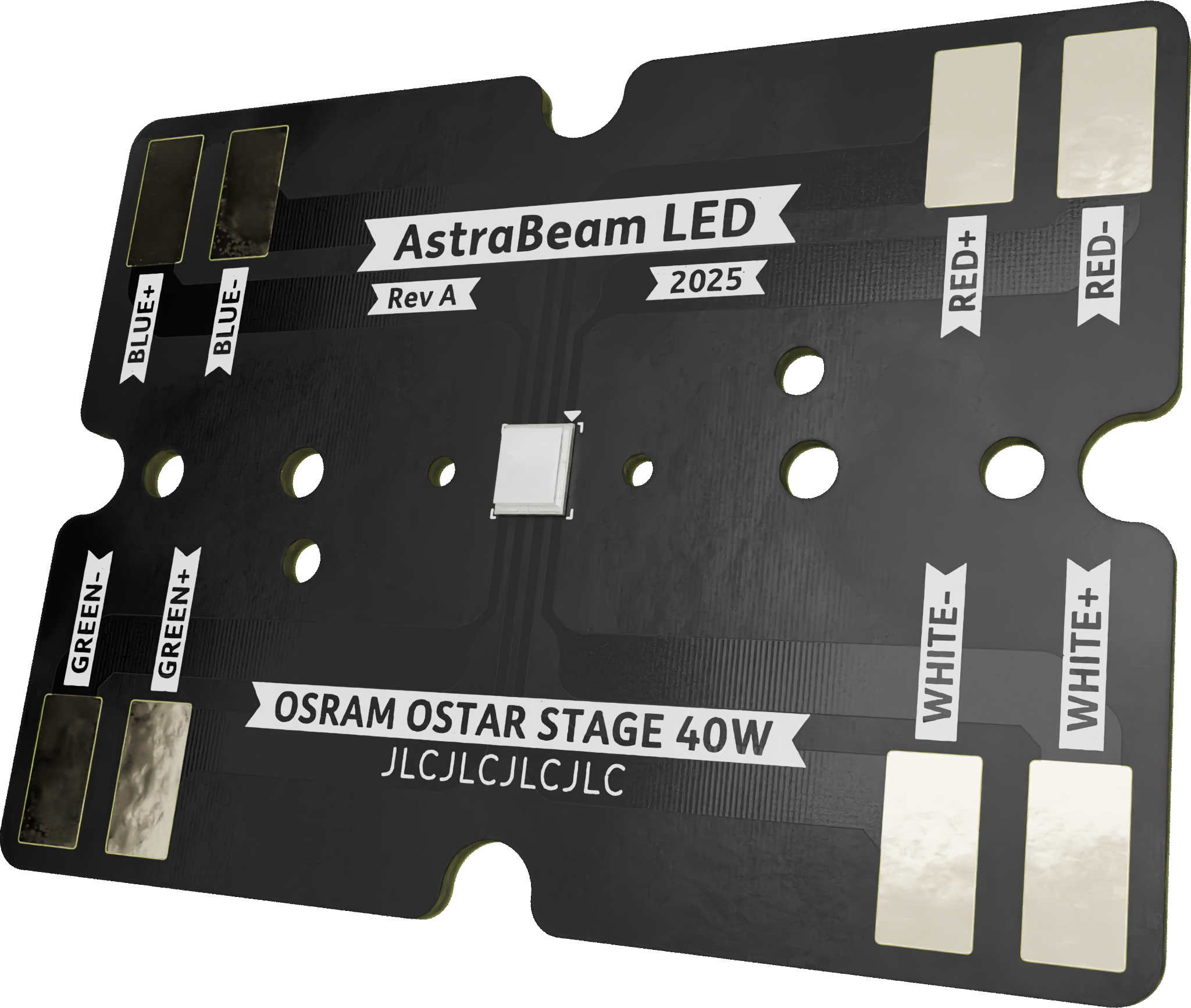

Render Top

Render Bottom

Interactive BOM

Easily check component locations by hovering over a specific component.

BOM

All components with Values, References, Sheetpath and Links to the datasheet.

KiCad Revision Inspector (KiRI)

KiCad Revision Inspector (KiRI) is a tool for comparing different versions of KiCad projects. It exports project revisions to SVG format for visual comparison using an onion skin view. This helps identify changes and errors in PCB designs. KiRI also includes a command line interface for generating viewable artifacts in any web browser.

View the PCB / Schematic in an interactive way, pan and zoom to see the details.

Dark

Light

Schematic

Dark

Monochromatic

Light

Assembly

Dark

Light

3D Step

Downloads

JLCPCB

Eurocircuits

Report

ERC

ERC Report

- Errors: 0

- Warnings: 0

- Link: HTML Report

DRC

DRC Report

- Errors: 0

- Warnings: 0

- Link: HTML Report

PCB

Board size: 75.0x55.0 mm (2.95x2.17 inches)

- This is the size of the rectangle that contains the board

- Thickness: 1.61 mm (63 mils)

- Material: FR4

- Finish: ENIG

- Layers: 2

- Copper thickness: 35 µm

Solder mask: TOP / BOTTOM

- Color: Top: #00000080 / Bottom: #0000002b

Silk screen: TOP / BOTTOM

- Color: White

Special features:

- Edge plating

Stackup:

| Name | Type | Color | Thickness [µm] | Material | Er | Loss tan |

|---|---|---|---|---|---|---|

| F.SilkS | Top Silk Screen | White | ||||

| F.Paste | Top Solder Paste | |||||

| F.Mask | Top Solder Mask | #00000080 | 10 | |||

| F.Cu | copper | 35 | ||||

| dielectric 1 | core | #8D5316ED | 1516 | FR4 | 4.4 | 0.020 |

| B.Cu | copper | 35 | ||||

| B.Mask | Bottom Solder Mask | #0000002B | 10 | |||

| B.Paste | Bottom Solder Paste | |||||

| B.SilkS | Bottom Silk Screen | White |

Important sizes

Clearance: 0.2 mm (8 mils)

Track width: 0.75 mm (30 mils)

- By design rules: 0.15 mm (6 mils)

Drill: N/A mm (N/A mils)

- Vias: N/A mm (N/A mils) [Design: 1.1 mm (43 mils)]

- Pads: N/A mm (N/A mils)

- The above values are real drill sizes, they add 0.1 mm (4 mils) to plated holes (PTH)

Via: N/A/N/A mm (N/A/N/A mils)

- By design rules: 0.3/1.0 mm (12/39 mils)

- Micro via: yes [0.2/0.1 mm (8/4 mils)]

- Buried/blind via: yes

- Total: 0 (thru: 0 buried/blind: 0 micro: 0)

Outer Annular Ring: N/A mm (N/A mils)

- By design rules: 0.1 mm (4 mils)

Eurocircuits class: 4A

- Using min drill N/A mm for an OAR of N/A mm

General stats

Components count: (SMD/THT)

- Top: 9/0 (SMD)

- Bottom: 0/0 (NONE)

Defined tracks:

- 0.35 mm (14 mils)

- 0.5 mm (20 mils)

- 0.75 mm (30 mils)

- 2.0 mm (79 mils)

- 4.0 mm (157 mils)

Used tracks:

- 0.75 mm (30 mils) (16) defined: yes

- 4.0 mm (157 mils) (24) defined: yes

Defined vias:

- 0.55/0.25 mm (22/10 mils)

- 0.7/0.3 mm (28/12 mils)

- 0.8/0.4 mm (31/16 mils)

Used vias:

Holes (excluding vias):

Oval holes:

Drill tools (including vias and computing adjusts and rounding):

Solder paste stats:

Using a paste with 87.75 % alloy, that has an specific gravity for the alloy of 7.4 g/cm³ and 1.0 g/cm³ for the flux. This paste has an specific gravity of 4.15 g/cm³.

The stencil thickness is 0.12 mm.

| Side | Pads with paste | Area [mm²] | Paste [g] |

|---|---|---|---|

| Total | 24 | 412.67 | 2.05 |

Note: this is just an approximation to the theoretical value. Margins of the solder mask and waste aren’t computed.

Credits

Amulet - Inspiration for awesome schematic and PCB

Sorry if I am forgetting someone, I used lots of references and tips from all over the place.